Wonder Workshop - Product Design Engineering

As a Product Design Engineer at Wonder Workshop, my responsibility for my first 14 months was primarily to act as Product Owner for Blaster Power for Cue, a smart dart-launching accessory for our latest robot. When I started the project, it was in its early prototyping phase so I truly got to experience and lead each step in the product development cycle. Being at a smaller company, I got to wear as many hats as I could manage wading deep into the waters developing the play experiences around the accessory early-on, improving functional performance from prototype to prototype, creating layouts and graphical elements for the instructions, traveling to southern China to push the product through prototype and pilot production builds to production start, and even expanding my programming skillset writing test tabs in our internal product testing iOS app.

After the launch of the Blaster Power accessory, I worked on the production of our revamped Dash robot dealing with cost-down, end-of-life component replacement, and increased production capacity initiatives. When I wasn’t in China supporting the production builds, I was also working on new product development for an entry-level robotic experience to augment the flagship Dash robot.

As a member of the Product Team, we frequently are tapped for brainstorms around new products, feedback on products going to market, and info sessions for potential or existing vendors. It is an exciting team to work for at an exciting company to be a part of and so I tried to leverage all of the benefits I could from my incredible and knowledgable teammates to expand my skillset and understanding as a product designer.

Blaster - Early prototyping

When I arrived at Wonder Workshop, I left for China to meet our CM in my second week and when I got back, the one Blaster prototype we had in the office was broken and torn apart, so my first task was to fix it, understand why it wasn’t working, and how we can improve it. At this point, functional criteria was loosely set, but the Blaster Power was slow to fire and could only shoot about three meters with the wind at its back. It also was unbalanced and would cause Cue to tip over when turning. Everyone was underwhelmed and we figured kids would be too, but to know where to set our sights we would have to conduct some user testing.

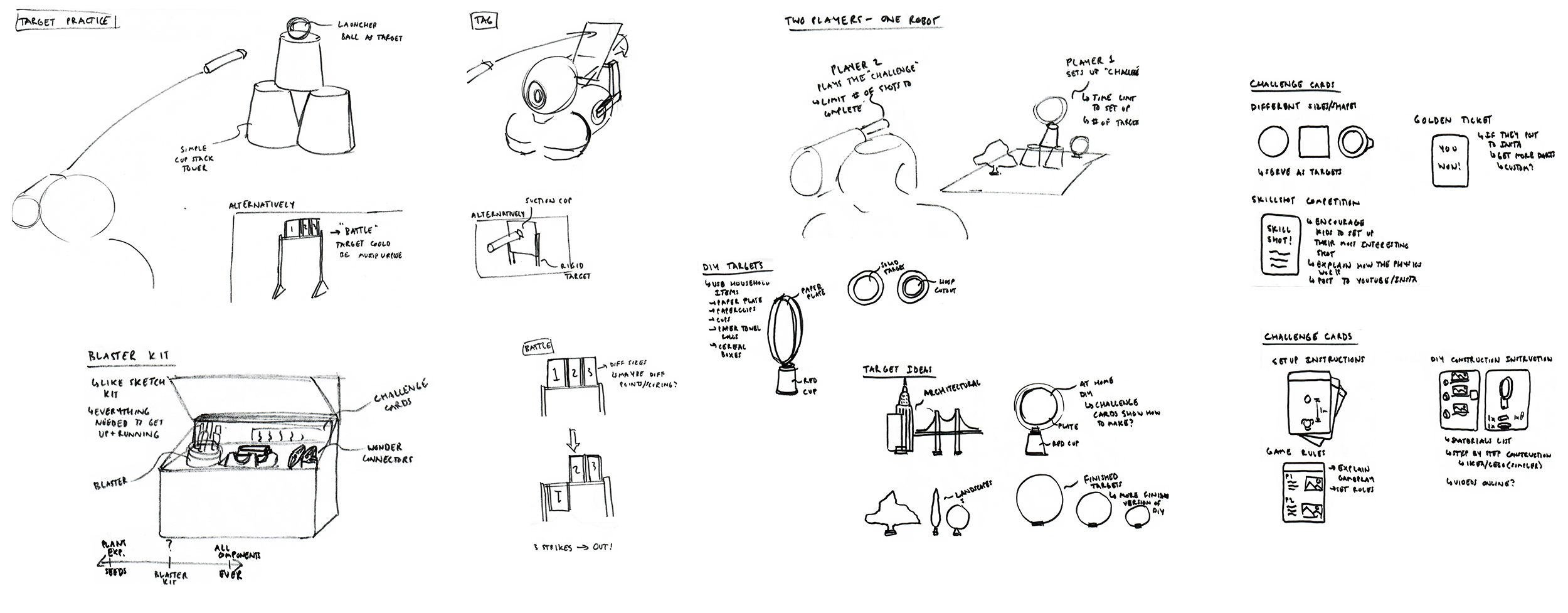

Blaster - Play experience definition

In order to better set functional criteria, we needed to understand what the use cases would be. Here I have some of my early half sheets of what that experience could look like. We conducted user testing sessions with kids in the Blaster Power age range and ran them through some of the scenarios to see what they wanted the Blaster to do. From these user testing sessions, we were able to feel better about setting our benchmarks for functional parameters such as time to fire, launch distance, time to load. We also were able to begin developing the experience that would be compelling to kids. We had a hunch that kids would naturally be drawn to a dart launching robot, but in order to make an educational and more focused experience we would need to provide exercises as scaffolding that would then inspire and empower the kids to create their own adventure.

Blaster - CM Production Support

I spent a lot of time in the air traveling to and from China in my time at Wonder Workshop. Traveling to China and working with our CM is both the most rewarding experience and the most frustrating experience; however, good and bad together it is an invaluable learning experience from both a product development perspective and people operations perspective. Being on the ground in China allows for questions or problems that pop up during the final prototype and early production phases to be handled in real time. Beyond making my work more efficient and also being an incredible learning experience as a young engineer, the relationships made with the people I have been fortunate enough to work with have been the best part. You are forced to think deeply about the motivations of who you are talking to and how you can most effectively communicate your ideas to achieve an end that is mutually beneficial.

Blaster - Getting started instructions

Being at a small company and on the team that is ultimately responsible for the successful production and shipping of the product as well as safeguarding the original product design intent, we get involved with all sorts of things that may not technically fall under our job description. One such thing that I happen to have experience in and actually quite enjoy is graphic design, in this case creating the initial designs for the instructions for the Blaster Power accessory. As this product will eventually be shipped in countries speaking over 12 different languages, the instructions could not have word explanations as they would have had to be translated 12 times, making it less of a “Start Here” card and more of a “Start Here” textbook. I started out creating the different blocks I thought I might need by hand and then moved into Illustrator to create the graphical elements and initial layout.

Blaster - Expanding my programming skillset

Touching again on being part of a small company, I try to leverage the flexibility that brings to my job by taking on challenges that I would not get to take on at a larger company. Having programming experience, I jumped at the opportunity to take on a project that many with the know-how did not want or were to busy to do: creating test tabs for our products in our internal debugging iOS app. I created all of the life test and functional test tabs for Blaster Power which made the above simultaneous life test of eight Blasters and Cues. I was even was tapped to create tabs for another product of ours after the team saw my work on Blaster Power. This jokingly earned me the title of “Full Stack Product Engineer” as I handled everything from brainstorming and early ideation sketching, to making ME and EE calls for production, to writing code for the quality assurance test apps.

Blaster - Final Product

After all of this was said and done, the Blaster Power for Cue was a full-blown robotic experience that had come a long way. There was a story behind it’s creation thanks to our creative director and his team, which sparked kids’ imaginations. There were challenges built and tested with real kids, which progressed in difficulty. Then of course there was the hardware itself that went from an unbalanced, slow to fire, 3 meter shooting dud to a stable, quick shot, 10 meter Blaster Power that expanded the world that the Cue robot could engage with and access.

Blaster - Seven days to launch

About a week before the Blaster Power was set to launch, my manager got a request for any videos we might have to promote the product. I jumped on the opportunity to try my hand at creating a product teaser video and started storyboarding different options right away; there was no time to lose. In the end I came up with three options ranging from simple, to medium difficulty, to likely impossible to create. I opted for the simple ad due to the schedule and resource constraints.

Blaster - Promo Video Shooting

After deciding on the ad direction, I roughed out the shots to make sure the framing would work how I wanted it to (left). Fortunately, I work with programmable robots, so I was able to program their path and get the shots just right. Once I had confirmed that things were lining up the way I wanted them to, it was time to add a little polish. I dropped a green screen behind the shot, borrowed all of the lights from our EE lab, and got to shooting the final shot (right). Note the blank cards. I was working on a tight timeline and shooting this mostly when the office was quiet because everyone had gone home for the day and so I did not have the final words for the cards from marketing by the time I was shooting. Cue the clichéd industry line, “We’ll fix it in post!”

Blaster - Final Promo Video

A few late nights with more than a few hours in After Effects, Premiere Pro, and Logic Pro X for the music, we had a video. It was my first professional foray into product video production and I certainly learned a lot and was excited by the compressed schedule and limited resources to make this work. From concept to shipping in seven days. On the day of the product launch, this video was posted to all our social media outlets to promote the brand new product that I had spent over a year developing: Blaster Power for Cue!

Promotional Conference Demos

Being on the product team, we get tapped for brainstorms and also to help with building out ideas for other teams. This past conference season, my colleague and I were tasked with coming up with DIY looking demos to showcase our new Gripper Building Kit accessory for Dash and Cue. The brief was it had to be simple (understood in 30 seconds), debuggable by an inexperienced user, and, to make it fun, a little random. What we end up creating were a shuffleboard mixed with skee ball game and a match the peg to the slot game for Cue and Dash respectively.